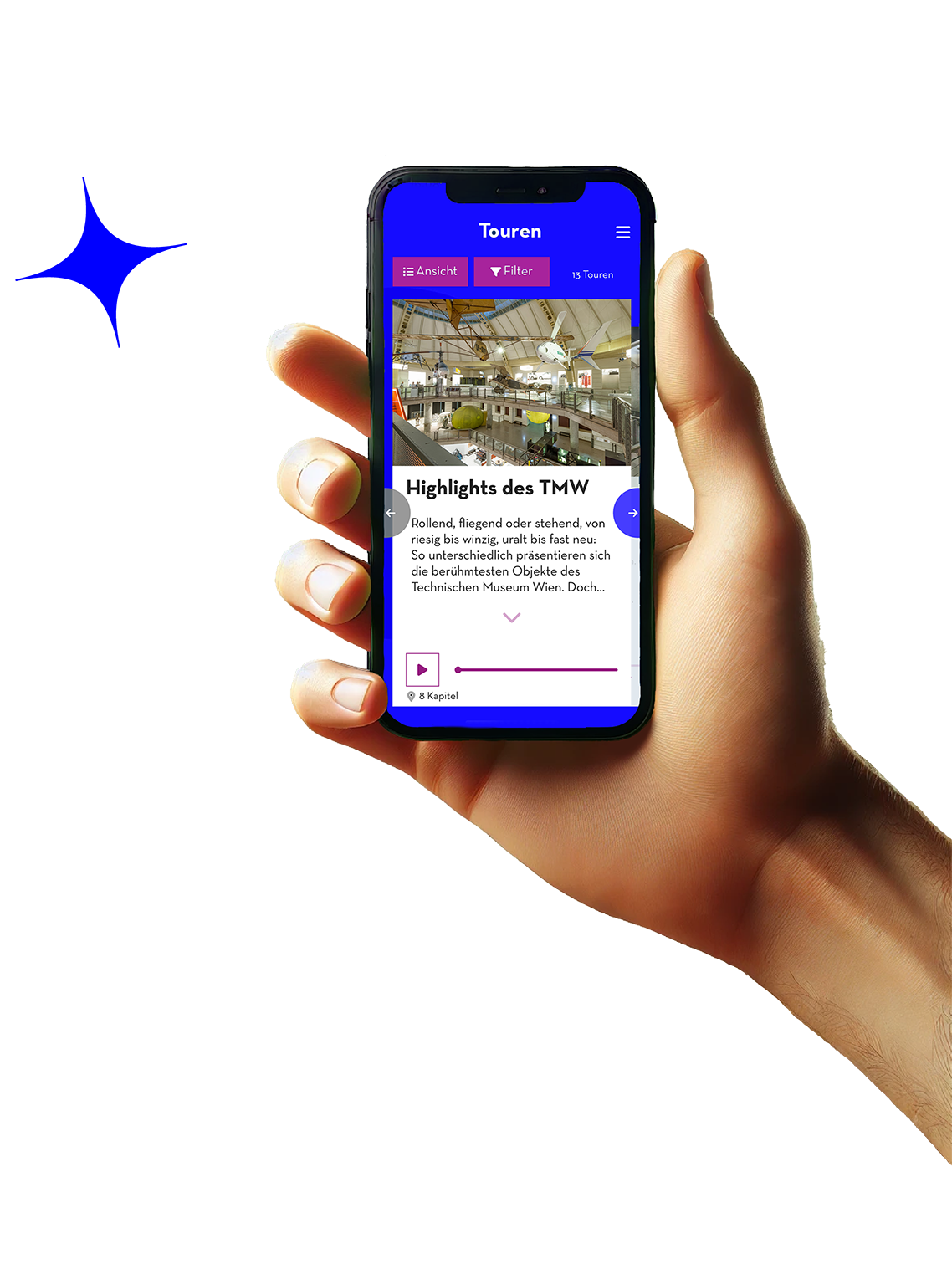

Sei Neugierig - im Technischen Museum Wien

In unseren vielfältigen Ausstellungen treten historische Objekte in einen Dialog mit neuen Technologien. Spannende Vermittlungsprogramme erwecken unsere Exponate zum Leben und zahlreiche Hands-On-Experimente laden ebenso wie unsere Rätselrallyes zum Mitmachen und Ausprobieren ein. AHA-Momente garantiert!

PLANEN SIE IHREN BESUCH - WIR EMPFEHLEN FÜR

Ausstellungen

Heute im TMW

Für alle

Ab 10 Jahren

Führung / Aktion

€ 3,90

Mi 02.07.10:30–11:00

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.11:00–11:30

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.11:30–12:00

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.12:00–12:30

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.13:00–13:30

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.13:30–14:00

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.14:00–14:30

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.15:00–15:30

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.15:30–16:00

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.16:30–17:00

Führung / Aktion

4 Plätze frei

€ 3,90

Mi 02.07.17:00–17:30

Führung / Aktion

4 Plätze frei

€ 3,90

Kinder & Familie

3-8 Jahre

Reservierung Kinderbereich

€ 2,50

Mi 02.07.10:30–11:10

Reservierung Kinderbereich

40 Plätze frei

€ 2,50

Mi 02.07.11:30–12:10

Reservierung Kinderbereich

40 Plätze frei

€ 2,50

Mi 02.07.12:30–13:10

Reservierung Kinderbereich

37 Plätze frei

€ 2,50

Mi 02.07.14:00–14:40

Reservierung Kinderbereich

40 Plätze frei

€ 2,50

Mi 02.07.15:00–15:40

Reservierung Kinderbereich

40 Plätze frei

€ 2,50

Mi 02.07.16:00–16:40

Reservierung Kinderbereich

40 Plätze frei

€ 2,50

Mi 02.07.17:00–17:40

Reservierung Kinderbereich

40 Plätze frei

€ 2,50

Mi 02.07.11:00–11:40

Reservierung Kinderbereich

29 Plätze frei

€ 2,50

Mi 02.07.12:00–12:40

Reservierung Kinderbereich

35 Plätze frei

€ 2,50

Mi 02.07.13:00–13:40

Reservierung Kinderbereich

35 Plätze frei

€ 2,50

Mi 02.07.14:00–14:40

Reservierung Kinderbereich

35 Plätze frei

€ 2,50

Mi 02.07.15:00–15:40

Reservierung Kinderbereich

35 Plätze frei

€ 2,50

Mi 02.07.16:00–16:40

Reservierung Kinderbereich

35 Plätze frei

€ 2,50

Mi 02.07.17:00–17:40

Reservierung Kinderbereich

35 Plätze frei

€ 2,50